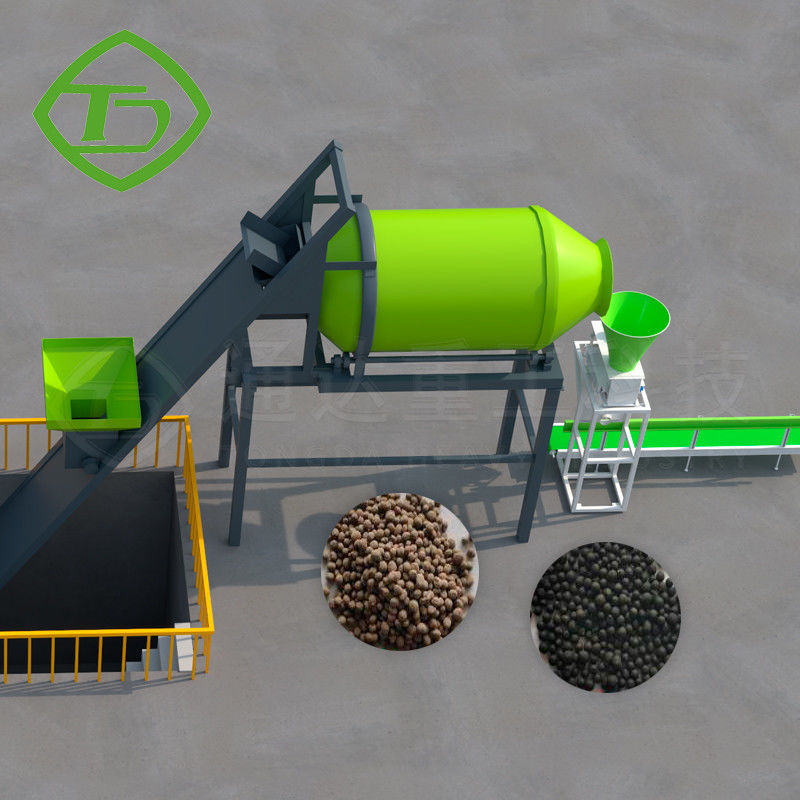

Higher Efficiency 10t/h NPK Bulk Blending Compound Fertilizer Line Bb Fertilizer Mixer Machine

The BB fertilizer production line is a special equipment for BB fertilizer batching, mixing and packaging that Tongda Heavy Industry

has successfully developed after years of research and development and combined with long-term practical experience in fertilizer factories.

The equipment has advanced technology, high degree of automation, convenient operation and maintenance, large output, small footprint,

long service life, and extremely high cost performance.

Product features and advantages:

1. Low requirements for plant buildings and low equipment investment Directly load materials on the ground, no raw material lifting equipment is required, and the production line occupies a small area.

2. Easy operation, maintenance and cleaning The batching system, mixing device and packaging system are all manually operated. In the manual state, each single machine can be operated independently, which brings great convenience to debugging, maintenance and cleaning.

3. Long service life The equipment adopts anti-corrosion measures such as stainless steel, and the main electrical parts are imported components. Through long-term operation in users, it has been proved that the performance is stable and reliable.

4. High cost performance A significant advantage of this production line is that it has a large output and a small investment.

The whole machine can be divided into three main parts:

1. Rack section: All working bodies of the machine are fixed on the rack, and the rack of the machine is welded with high-quality carbon steel plates and channel steel, and has passed strict process requirements to achieve the purpose of the machine;

Transmission connection part: The electric motor drives the belt pulley, V-belt, and reducer for transmission. The gears installed on the reducer mesh with the body gears, thereby driving the cylinder to work:

2. Working part of the cylinder: The cylinder part of the machine is made of high-quality carbon steel plate processed by special technology. The inner wall of the cylinder is equipped with special spiral stirring blades. While the cylinder is working, the material enters from the feeding port and is evenly stirred by the flipping and rotating of the special spiral stirring blades, avoiding the phenomenon of mixture diversion caused by different specific gravity and particle size during the downward flow process.

3. Climbing bucket feeding part: The climbing bucket feeding part of this machine adopts special process design. The guide rails of the climbing bucket are made of high-quality channel steel and designed with reasonable angles to ensure smooth overall operation. This solves the problem of difficult loading and easy deviation of the lifting bucket caused by height restrictions in the past.

BB fertilizer mixer parameter table:

|

Model

|

Output Capacity(L)

|

Feed Capacity(L)

|

Rotating Speed Of Mixer(r/min)

|

Productivity

(m³/h)

|

Supporting Power(kw)

|

Mixing And Lifting Motor (kw)

|

|

350

|

350

|

560

|

14

|

10~14

|

5.5

|

0.55

|

Characteristics of Performance:

1.The mixing efficiency is high and the area is small.The spiral blade adopts high – wear special alloy.

2.Adopts reducer transmission, which is stable and has low noise.

3.It has reasonable structure. Its feeding is from the top, and the discharging is from the bottom.

4.The joint surfaces are tightly sealed and run smoothly.

FAQ:

1. Are you trading company or manufacturer ?

We are a manufacturer with a history over 40 years and have realized one-stop service for design, manufacture, installation, debugging and technical training.

2. How long is the delivery time?

For standard machines or Components, it would be 5-10 days; For non-standard machines and customized machines according to clients specific requirements, it would be appointment time.

3. Do you arrange shipment for the machines?

Yes, we will do that. For FOB or CIF price, we will arrange shipment for you. For EXW price, we will assist you in arranging shipment.

4. How about your product after-sales service?

Normally we provide video and written technical support. If necessary, our engineers can also provide on-site service. Our product accessories can be selected according to the actual needs of the customer to choose the most appropriate way to deliver.

5. What kinds of certificate you have?

ISO 9001: 2015 SGS and we can make other certificates according to customers' detailed requirements.

6. How to guarantee the quality and operation before loading?

We have our own quality control department and have advance quality control stystem while from raw materials to finished products. All the machines and production lines shall be 100% checked and tested before delivery.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!